Introduction to Plastic Injection Molding

Many people have heard of plastic injection molding before but are not quite sure what it is or how to find a quality plastic injection molding manufacturer. This blog article explains in detail the process of creating plastic objects from thin granules.

What is Plastic Injection Molding?

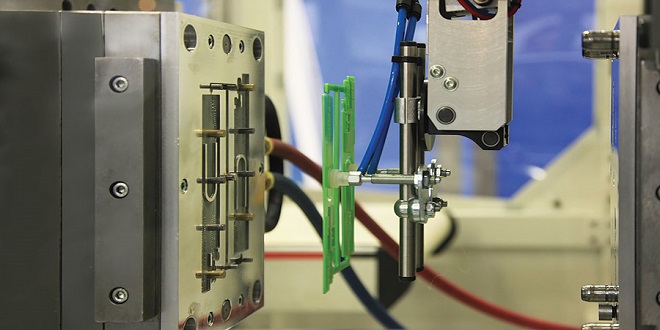

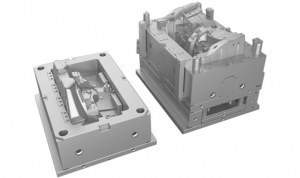

Plastic injection molding is a process used to create plastic parts by injection molding. In this process, an object is formed from a thermoplastic resin that is heated until it solidifies and is injected into a metal mold. The molten plastic is forced into the mold, where it cools and hardens. This process creates parts of many different shapes and sizes, which can be used in products such as cars, appliances, toys, and medical devices.

One of the most important aspects of plastic injection molding is the quality of the used plastics. Because this process can create objects with extremely detailed shapes, the plastic used must be capable of withstanding high temperatures and pressures. In addition, it is important to choose plastics resistant to chemicals and other substances that may be encountered during manufacturing.

Overall, plastic injection molding is an intricate process that produces many different types of products. It is an essential part of modern manufacturing and should be considered when planning any project that requires a high degree of detail or durability.

Why is it Popular?

Plastic injection molding is a process that creates plastic parts from a CAD file. The process begins with creating a 3D model of the part and then sending it to the machine. Next, the machine uses heat and pressure to create the plastic part. This process is very easy to use, affordable and doesn’t require any special skills.

Plastic injection molding is very popular because it’s a fast and easy way to create plastic parts. You can create parts in hours instead of days or weeks. Plus, it’s a low-cost method that can produce high-quality parts.

What are the Advantages of Using a Qualified Manufacturer for Plastic Injection Molds?

There are many advantages to using a qualified manufacturer for plastic injection molding. One of the most important advantages is that you can be confident that the product will meet your specific needs and expectations. A qualified manufacturer will have experience with plastic injection molding, which means they can produce products that meet your specifications perfectly. Additionally, using a qualified manufacturer can save you time and money.

Conclusion

If you are considering plastic injection molding as a way to produce high-quality products, this introduction is for you. Also, by working with a qualified manufacturer, you’ll avoid having to learn new techniques or tackle difficult problems on your own.