Power steering systems Rack-and-pinion steering

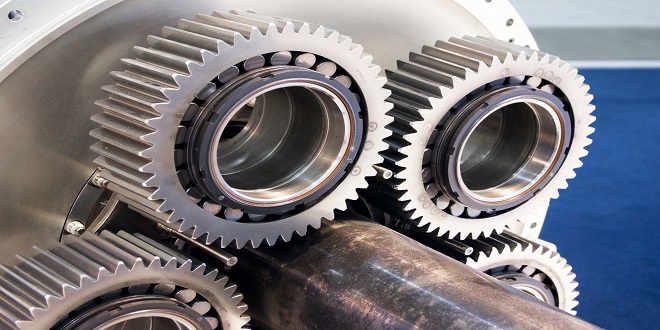

Rack-and-pinion steering is found on most modern passenger vehicles. The pinion is a gear that connects to the shaft of the steering wheel. The rack has notches cut in it that engage the teeth on the pinion gear. Each end of the rack connects to an inner and outer tie rod, which connects to the control arm, which connects to the spindle on the wheel at that side of the vehicle.

As the steering wheel turns, the gear turns, moving the rack, which moves the tie rods, which cause the wheels to turn. A rotary valve senses whether the driver is turning the steering wheel or just driving straight ahead. It does this via a steering shaft that connects to the steering wheel at one end and to the pinion gear at the other.

As the steering wheel turns, the torsion bar twists and the pinion gear responds accordingly. Rack-and-pinion power steering is powered in two basic ways. Other steering systems described may work on the same principles, but the clearest way to view them is to relate them to rack-and-pinion systems.

When power steering was first introduced, it was intended to help drivers of large or heavy vehicles to steer more easily when parking or heading around curves. Then it became a luxury option for passenger vehicles. Today, virtually every vehicle on the road comes equipped with a power steering system. This section describes the most popular types of power steering.

Three types of power steering systems are in use today or are scheduled to make their appearance in a very short time: rack-and-pinion, recirculating ball, and steer-by-wire. The following sections take a closer look at each of them

connected to the engine by a belt wrapped around a pulley. As vanes inside the pump turn in response to the speed of the engine, they force power-steering fluid under hydraulic pressure into a piston located at the center of the rack. As you can see the hydraulic piston has an opening on either side of it that allows the fluid to enter.

The direction in which which the steering wheel is turned forces the fluid into one side of the piston or the other. This causes the piston to move the rack in that direction, which moves the tie rods and the wheels accordingly.

Recirculating-ball steering

Another type of steering system most often found on trucks and SUVs is called recirculating-ball steering because it features a recirculating-ball gear. The outer part is a block that has a hole in it and gear teeth on the exterior. A rod with threads at one end screws into the threads inside the hole.

The threads in the rod are filled with ball bearings that reduce friction between the threads in the rod and the threads in the hole and keep the rod moving firmly in place. The rod is connected to the steering wheel at the other end. When you turn the steering wheel, it turns the rod, which turns the block it’s screwed into.

Last word

The gear teeth on the outside of the block move the wheels in whatever direction the block is turning in response to the steering wheel. If the system is power-assisted, the power-steering pump sends hydraulic fluid under higher pressure to one side of the block or the other, depending on which way the steering wheel is turned.